FUNCTIONING

Operating principle

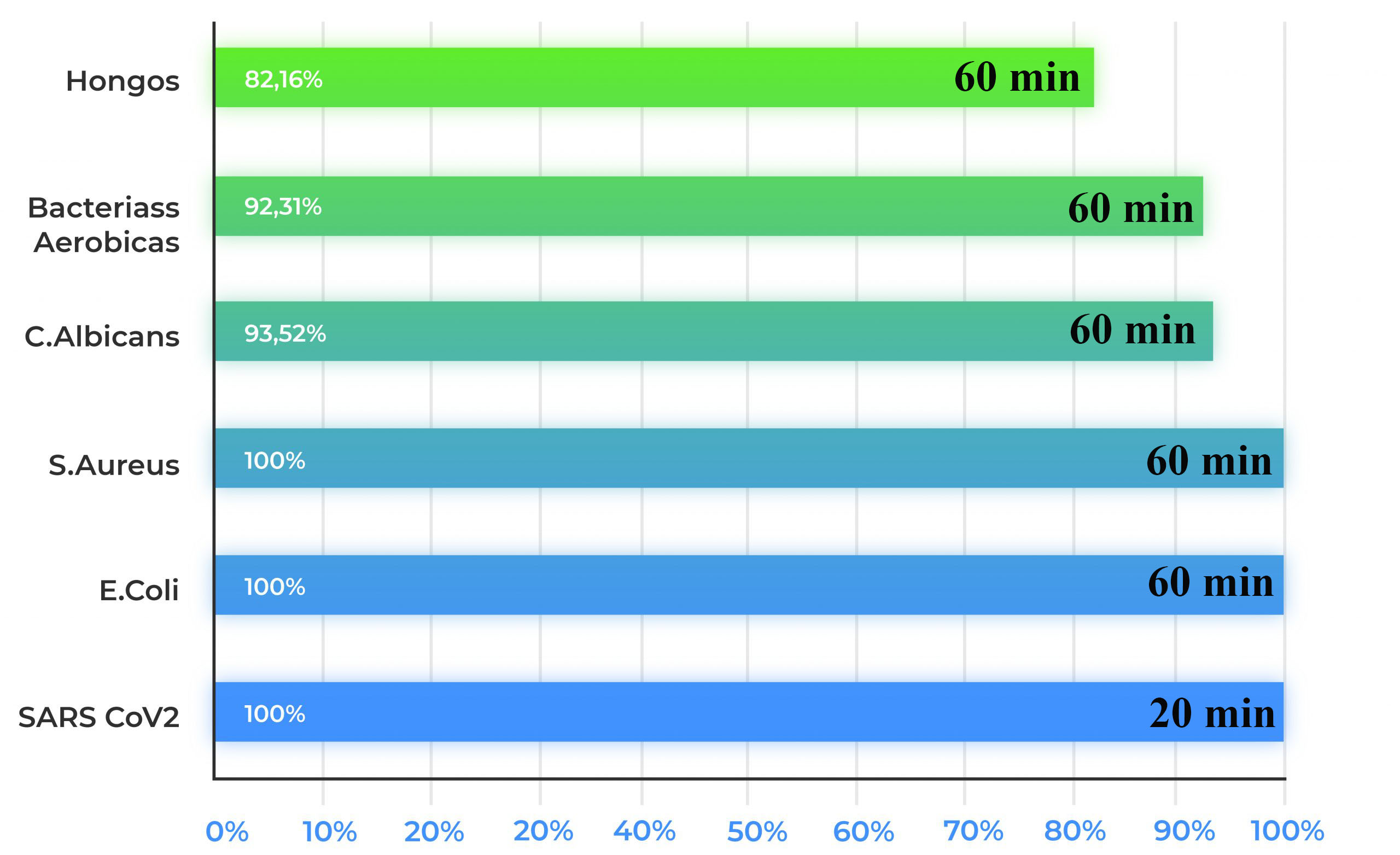

The effectiveness tests are carried out by the R.Reig Laboratory (Spain) in a space of 35m3.

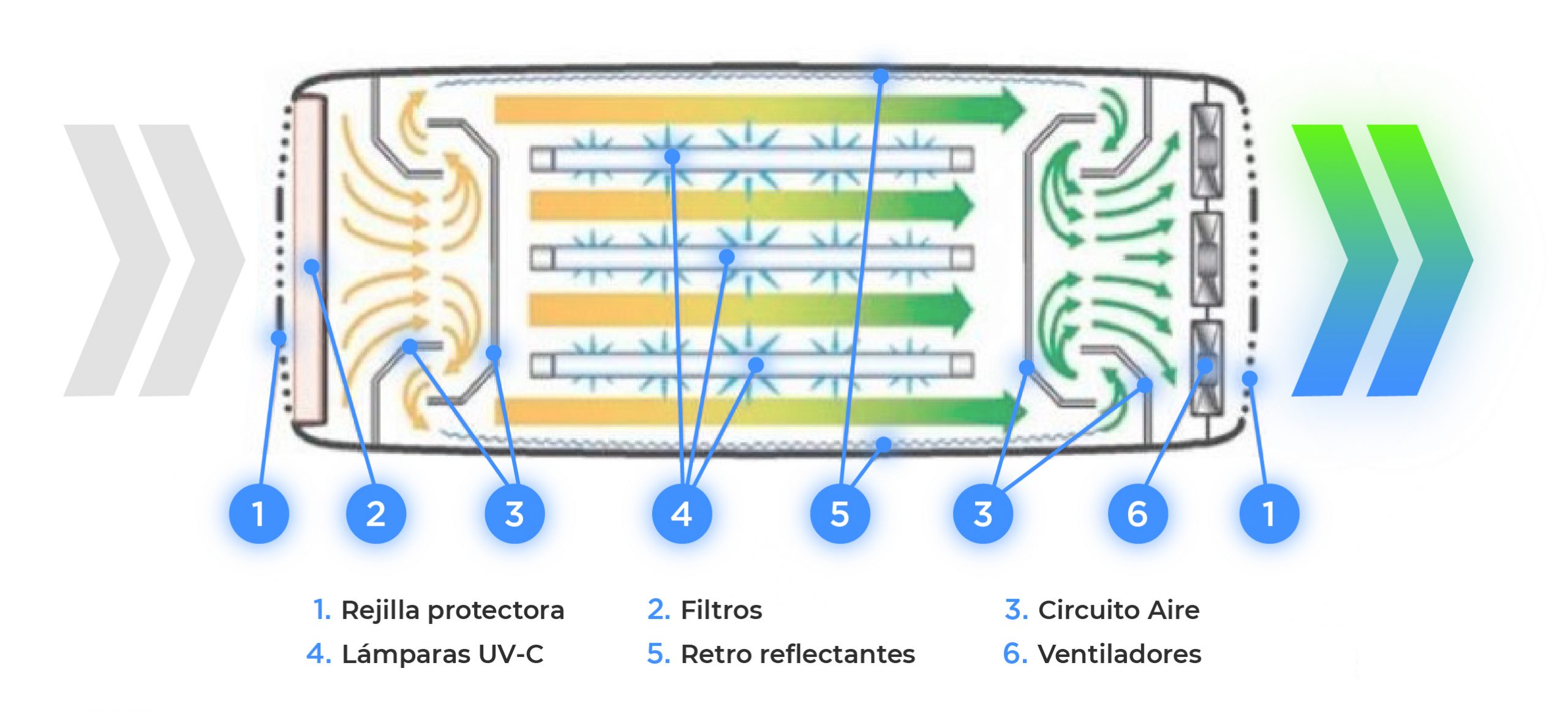

Our solution is based on a simple system, which allows the air flow to circulate through the interior of the equipment, previously passing through filters that only retain dust and mites.

The equipment has several UV-C lamps that project the light inside an aluminum chamber. The airflow passes through the chamber, the walls of which reflect the light beam, generating enough energy to destroy or inactivate the pathogens present. After this process, the completely sterilized air is expelled.

The lamps have a special coating that captures radiation of less than 200 nm, thus preventing the formation of ozone in the air and prolonging the life of the lamps up to 18,000 hours at the same time.

Why UV-C technology ?

HEPA

|

||

| Proven efficacy in elimination of viruses, bacteria and fungi | ||

| Optimal cost-effectiveness | ||

| Fast processing | ||

| Operation in the presence of people, animals and plants | ||

| Availability of permanent operation | ||

| Low annual maintenance cost (replacement parts) | ||

| Low monthly consumption | ||

| Easy to use (no special personnel required) | ||

| 99.99% efficacy against SAR-CoV-2 | ||

| Long service life | ||

| Does not emit toxins | ||

| Easy recycling | ||

| Universal use (in all types of spaces) |

ASHRAE recommendations * |

DESAIR |

||

| Banks of UV-lamps installed inside HVAC units or associated ductwork; positioned parallel or perpendicular to airflow. Requires increased dose of UV to inactivate microorganisms on-the-fly as they pass through the disinfection zone. Due to limited exposure time, installations should observe these guidelines: | D-50 | D5 / D7 | D3 / D4 |

| Minimum target UV dose of 1,500 µW•s/cm2 (1,500 µJ/cm2) | 3985 | 3248 | 1949 |

| Designed for 500 fpm or slower moving airstream | 453 | 462 | 462 |

| Minimum irradiance zone of 2 feet | 2 | 2,3 | 2,3 |

| Minimum UV exposure time of 0.25 second | 0,271 | 0,286 | 0,286 |

ASHRAE recommendations * |

DESAIR |

|||

| Banks of UV-lamps installed inside HVAC units or associated ductwork; positioned parallel or perpendicular to airflow. Requires increased dose of UV to inactivate microorganisms on-the-fly as they pass through the disinfection zone. Due to limited exposure time, installations should observe these guidelines: | D-50 | D5 / D7 | D3 / D4 | D2 |

| Minimum target UV dose of 1,500 µW•s/cm2 (1,500 µJ/cm2) | 3985 | 3248 | 1949 | 1206 |

| Designed for 500 fpm or slower moving airstream | 453 | 462 | 462 | 277 |

| Minimum irradiance zone of 2 feet | 2 | 2,3 | 2,3 | 2 |

| Minimum UV exposure time of 0.25 second | 0,271 | 0,286 | 0,286 | 0,349 |

Details on the UV Dose Recommendation for SARS-CoV-2: SARS-CoV-2:

A conservative minimum UV-C (254 nm) dose value of 1,500 µJ/cm2 is therefore suggested for 99% inactivation of SARS-CoV-2 in air.

A minimum UV-C (254 nm) dose of 611 µJ/cm2 should be applied for 90% inactivation of SARS-CoV-2. This extrapolates to a dose of 1222 µJ/cm2 for 99% inactivation of SARS-CoV-2 virus in air applications.TECHNOLOGY

Proven efficient technology

UV-C disinfection

UV-C against microorganisms

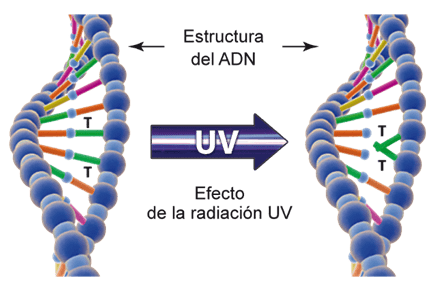

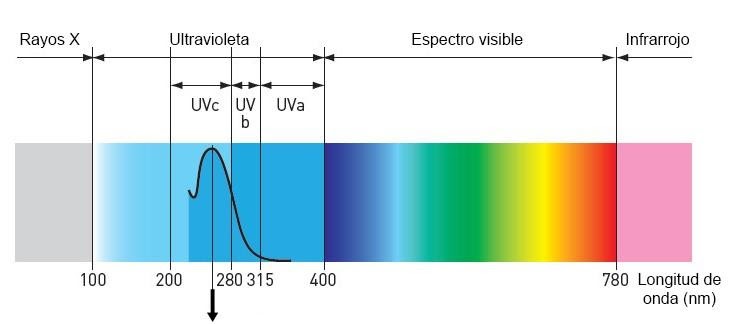

At the wavelength of 253.7nm it is precisely where the necessary energy is produced to penetrate the wall that protects the genetic information of the microorganisms.

UVC works by breaking down DNA / RNA, thus inactivating its ability to reproduce and infect.

short wavelength

UV-C light

Ultraviolet Light is an emission of electromagnetic waves whose wavelength is between 100 and 400 nm (nanometers). Precisely in the segment of the band between 200 and 280 nm, commonly known as short-wave UV (UV-C), is 253.7nm, this being the most effective as a germicidal function.

UV-C radiation is an air and object disinfectant solution that can help mitigate the risk of infection and has been widely used for over 40 years. All bacteria and viruses tested to date (many hundreds over the years, including various coronaviruses) respond to ultraviolet UV-C disinfection. A clear indication that UV radiation can play an important role in the protection strategy.

UV-C light is used for air disinfection in practically all applications, because there are always situations where microorganisms in the air can cause problems and make people sick. For example, in offices and schools, public transportation, entertainment venues, but also in the food processing and agricultural industry. Microorganisms in the air can be easily and effectively inactivated by UV-C light.

HISTORY

A little history of the UV-C light

Technology used for over 100 years

Ultraviolet radiation has been widely used by scientists for over 100 years, UVC radiation is a known disinfectant for disinfection of air, surfaces, and water.

-

Demonstration of its bactericidal effect – 1877

A detailed study of the effects of the UV-C electromagnetic radiation spectrum by English scientists Doyney Blount demonstrated the bactericidal effect of UV radiation in 1877. This was the historical benchmark for the successful use of this physical discovery in medicine.

-

Against pathogenic bacteria – 1892

In 1892 the English scientist Harry Marshall Ward showed that a part of the UV-C electromagnetic spectrum destroys pathogenic bacteria.

-

First lamp - 1904

An important contribution was also made by Richard Koch, when in 1904 he created the first mercury quartz lamp, which served as a powerful source of bactericidal disinfection.

-

First laboratory tests - 1920s

In the 1920s, the first laboratory tests of UV radiation were carried out with successful results in the fight against infections that are transmitted through the air.

-

Use in Medicine - 1930

In 1930 ultraviolet radiation began to be actively used in medicine.

-

Operating room disinfection - 1936

In 1936 in the United States, ultraviolet radiation was used for the first time to disinfect the air in operating rooms, it was when the level of postoperative infections began to be significantly reduced.

-

Ventilation systems - 1937

In 1937 the field of use of UV-C disinfection was expanded and UV-C lamps of this type were used for the first time in an American school They incorporated an ultraviolet bactericidal irradiator into the school's ventilation system, the result of which was a considerable reduction in the incidence of various airborne infections, including measles, which was common at the time.

-

Disinfection in the absence of people - 1980s

The practice of UV-C lamp disinfection was used successfully until the 1980s. However, this type of lamp produced ozone formation, toxic to humans at certain concentrations. Therefore, it was essential to carry out UV disinfections in the absence of people and with a mandatory rear ventilation of the interior before entering people.

-

Disinfection in the presence of people - 1994

1994 A group of Russian scientists have patented the DESAIR closed-type air disinfector, which is a recirculator with an ozone-free lamp.

-

Present

2020 The newest D-50 model is made of anodized aluminum with a patented coating of nano silver particles on the body with 99.99% disinfection effectiveness.